The power of observation

Sometimes a low-tech approach is the right solution to your operational problems…

Firstly, let’s get it out of the way — this article is not hating on the use of business intelligence tools or analytical reporting. It’s purpose is to illuminate the benefit of using your own eyes when looking to improve your teams’ performance.

What do we mean by observation?

Observation in this article can be defined as: ‘the act of observing with your own eyes any task or process being completed by any of your team members.’ The purpose of the observation is to provide greater clarity on what is actually occurring versus what you expect to occur.

It is through this low-tech variance analysis that high-caliber leaders with a decent understanding of the work completed by their team members, can pin-point opportunities for improvement and often implement them rapidly.

What’s the background here?

We at Bramble have spent our careers working with operational managers across a range of industries on continuous improvement programs. Through our experience we realized that there are frequent commonalities shared by frontline leaders regardless of industry. These are:

- The best processors often become managers. Besides the questions that arise from effectiveness when this occurs, we also see a blind-spot appear — these managers assume their staff get through their work the same way as they did.

- There is a reluctance to question the way things are done. Even when a process is obviously unnecessary or antiquated, the frontline manager will rarely challenge or improve on it. This is typically because managers feel too busy just keeping their head above water to work on the business.

- A surface-level understanding of, and usage of performance reporting — it’s alarming how many leaders do not understand how the metrics they supposedly use on a daily basis are derived. This isn’t necessarily an indictment on the manager…more organizations need to look at the effectiveness of their operational reporting.

- They spend too much time doing the work rather than leading the team. They will happily dive in and process tasks when the need arises, get involved with escalations and of course complete the administration associated with being a manager. All this takes time away from planning, leading, organizing and control the flow of work and resources at their disposal.

- They think in silos. It’s not their fault, they are trained to make sure service levels are met and backlogs kept low across their domain…there’s no emphasis on the best utilization of their staff when expanded to think of the entire business.

Now this article is hyper-focused on the role the manager can play in improving team performance via observation. It doesn’t attempt to address all the commonalities listed above. Check out these articles for a broader conversation around team performance and the role of a leader.

Now, back to observation.

A lot of companies have performance metrics in place. Frequently, these are built on a foundation of benchmarking. Benchmarking via comparisons to the team average, historical performance or even industry best practices. We covered benchmarking in-detail here. The unit of measure (widget vs. time) is irrelevant.

The traditional approaches to performance reporting are flawed. They fail to cast any light at all on why variance may be occurring. They also fail to incorporate the ‘ideal-state’ of your process flow.

It is only through benchmarking current performance against the optimized state of your current processes that you will obtain a clear picture of just how much room for improvement your team has. Think of it this way, at the Olympics we don’t average out the time of the 8 finalists in the 100m to determine the world record.

How do you establish the ‘ideal-state’ of your process? Via observation.

So what’s the point of observation?

There are two reasons to incorporate observation into your toolkit:

- It’ll allow you to derive expectations/benchmarks which illustrate the gap between current performance and ‘perfect-world’ performance.

- Ongoing, it allows you to pin-point exactly the reason a team member is underperforming and determine the best course of action…almost immediately.

We are not encouraging managers to drop everything they are doing and instead start watching over their staffs’ shoulders! Instead we are suggesting that if you have identified a performance gap, then you’d be well-served to spend a couple of hours on an as-needed basis literally watching your staff member complete the tasks at hand. It’s a very simple yet effective tool as almost immediately you’ll be able to ascertain the best solution.

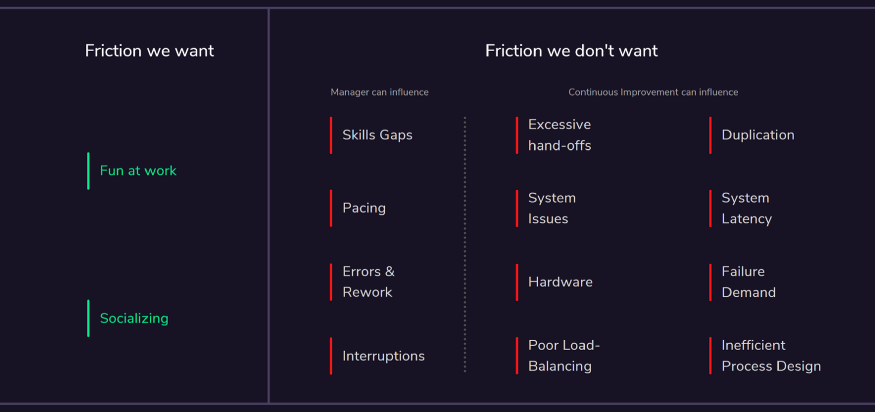

And it’s important to note that not every root-cause can be addressed by you, the frontline leader. There’s going to be friction that is out of your control. In those scenarios the observations becomes a useful data-point to share with your continuous improvement or transformation teams.

You’ll be surprised at how many ‘one-percent’ improvements you can extract from your team through observation. As an added bonus, the solutions are quite often implemented via additional training or clarification — not a costly and time-consuming project.

Some examples we’ve seen over our careers:

- Almost every client we have ever worked with has seen an uplift in performance by simply reducing the amount of team member to team member interruptions within their team. The root-cause is almost always a training or a confidence issue — the team member doesn’t know the process well enough or doesn’t have enough confidence to pull the trigger on a decision so they have their teammate check their work — in isolation, it is not a bad thing…however when repeatedly occurring it does create significant friction. The good news is both root-causes are extremely coachable.

- Another client was anecdotally aware of a third-party system causing considerable friction through latency yet they lacked any sort of comprehensive sizing of the issue until their leaders observed the impact on team members. Very quickly it went from a 10-second issue that each team member had to deal with 50 times a day (that we can’t do anything about and is too insignificant anyway) to a data-rich conversation with the vendor which led to an immediate fix saving $500k per year in staff member time.

- Within one client’s administration department, the team members actually called out that they didn’t have enough work in their queue to keep them productive! By cultivating an environment where staff were not afraid to call out when they have capacity, the client was able to identify just how much capacity was available and then implement cross-skilling allowing for sharing of staff members with their mail department.

Taken individually, a one-percent gain via observation isn’t that exciting…but when you stack 10, 15 or 20 ideas you’ll soon realize how much capacity you can create…all at the cost of a couple of hours of your time infrequently spent observing your staff work through their day.