- Published on

The 4 typical ways to benchmark individual performance…

- Authors

-

-

- Name

- Dan Wain

- in/danielwain0028

-

…and why they could be ineffective.

Do you know the capacity of your operation?

Most companies have performance metrics in place. Frequently, built on a foundation of benchmarking. Benchmarking via comparisons to the team average, historical performance or industry best practices. The unit of measure will vary depending on the client and the function however its’ fair to say benchmarks built on volumes, time or dollars are common.

In this article we will cover:

- the establishment of those benchmarks.

- Introduce the concept of friction within an operational environment and how to ensure wastage is removed from the benchmarks you set.

- Put forward a methodology for establishing benchmarks that is fair to employees while also ensuring the current performance is compared against current capability.

Traditional approaches

Over our career the most common ways that we have encountered to establish a yard-stick are:

- Conduct a time-and-motion study across a range staff members, then set the average output as the benchmark

- Use workflow time-stamp data across all in-scope staff to determine the average output and set that as the benchmark

- Use system generated data to determine where our staff are spending their time (i.e. how long is spent in each system) and then compare actuals against the team average

- Normalized performance metrics across the team — ensuring you always have performers in each quartile quadrant

- Self-reporting & screen-scraping — don’t even get us started on those!

The downside to these approaches is they inherently limit the performance ceiling in your organization. The tell here is the word average. If you are basing your performance metrics on averages, you’ll get consistently average results.

We don’t average out the time of the 8 finalists in the 100m to determine the world record.

Mathematically, there’s nothing wrong with the aforementioned approaches, our issue is a philosophical one — by applying one of the 4 methods you are still in the dark on the true capability of your process — you don’t actually know what fully-optimized looks like.

These methods also make it quite difficult to get to the root-causes of variances across performance. They fail to cast any light at all on why variance may be occurring.

Isn’t it better to benchmark performance against the ‘ideal’ than the average?

The ‘ideal’ approach to establishing benchmarks and optimizing performance

It is only through benchmarking current performance against the optimized state of your current processes, that you will obtain a clear picture of just how much room for improvement your team has. Think of it this way, at the Olympics we don’t average out the time of the 8 finalists in the 100m to determine the world record.

Below is Bramble’s recommended approach to setting benchmarks that generate sustainable performance improvement, inform process/automation initiatives & generate meaningful discussion between frontline leaders and staff members.

- Select a sample of employees that produce high-quality, solid output. Ask the team leader; ‘if you could clone 3 staff members who would they be?’. Then go and observe them completing their work (preferably tasks that constitute a high proportion of team volumes) for a few hours.

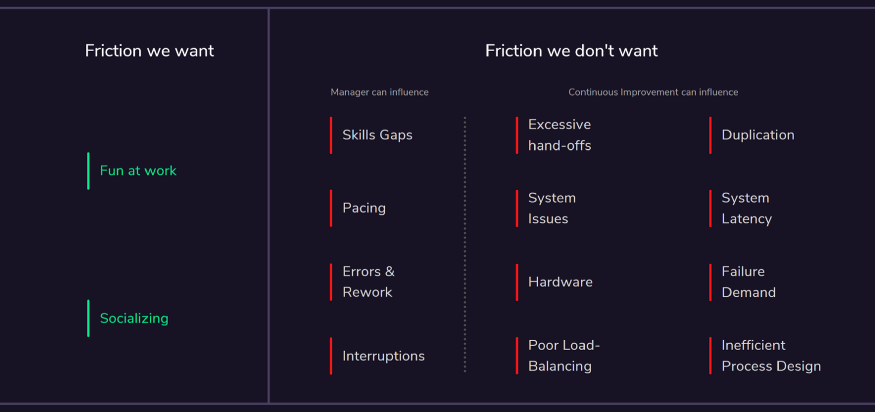

- When observing, make sure you’re recording the time spent on value-added components versus the time lost on non-value add components -friction (the screenshot below provides some examples of friction).

- Involve the staff member! Show them your findings, ask them if what you’ve observed is normal, ask them if they have any ideas for improving the process. Be as transparent as you can be as the data collected from these observations will be used to establish the benchmarks

- Involve the team manager! Encourage them to do some observations themselves. Share your findings with them and get their feedback. Most importantly, when the time comes to actually establish the benchmark you must include them in the process. From a behavioral and sustainability perspective, it is vital that the frontline manager signs off the benchmarks that will be used to derive performance metrics they and their team members will be held accountable to.

- When establishing the benchmark, remove any friction you observed from the sample. This ensures that you won’t bake in any sub-standard processes or behaviors into the benchmark. Finally, working with the manager, set the benchmark by determining the top-quartile performance across the core tasks of the team.

- Revisit the benchmarks once per year. They are dynamic. As a team becomes more productive, and as processes and systems are improved, the benchmarks should move along with them.

Friction — the hidden productivity killer.

And…that’s it. There’s not much magic to it - but by observing key tasks and setting benchmarks that are devoid of friction, you will be setting performance metrics that are a much better reflection of the processes in place, and providing an aspirational target for team members.